All About Commercial Roof Flashing: What You Need to Know

While you may not think about them regularly, your commercial roofing system and its flashings are instrumental in ensuring the longevity, safety, and success of your business. When rainwater penetrates your building through your roof, it tends to make wet, unsightly spots on the walls and ceilings. Not only are water stains unpleasant to look at; but long-term water exposure also poses safety and health risks, causing mold and pests or compromising the structural integrity of your building. The good thing is that roof flashings exist to keep these problems at bay in the first place.

Flashing serves as a moisture barrier that seals off the joints and seams of a roof using water-proof materials. This often goes a long way in avoiding leaks. Because roof flashing plays such a huge role in preventing water leakage, it’s a good idea to read up on it and understand it from every angle. International Construction Services, Inc., the leading commercial roof replacement contractor in the region, shares everything you need to know about it.

What is Commercial Roof Flashing?

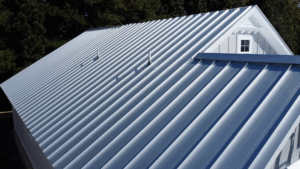

Commercial roofs often have a low-slope structure, designed to gently shed water over a shallow angle toward downspouts, gutters, and internal drains. With different roofing materials meeting at several points, gaps between them are often a challenge. Roof flashing installed during commercial roof repair or replacement safely covers those gaps.

Roof flashing comes in two major types:

- A thin, yet strong and flexible metal that is waterproof and easily formed to fit gaps between dissimilar materials.

- Plastic and rubber flashing that is also water-resistant and easily shaped, and won’t break down by touching incompatible materials.

Other common flashing materials include the same ones used in single-ply membranes such as TPO or PVC. These materials can be installed separately, in additional layers, around HVAC systems and other building protrusions. Galvanized steel, copper sheets, and even lead can also be applied by industrial roofing installers as flashing.

Where is Flashing Installed?

Flashing offers a multitude of functions around a commercial roofing system:

- Bargeboard — flashing installed along sloped roof edges

- Cap — flashing (typically metal sheets) shielding the upper edges of the roof membrane, above a wall or column.

- Drip Edge — flashing applied on the roof’s perimeter

- Eaves — flashing that runs along the length of a roof’s flat edges

- Saddle — flashing that bridges the gaps between incompatible materials

- Valley — flashing that covers the area where two downward roofing slopes meet

- Vent — flashing that wraps roof protrusions, such as vents and chimneys

- Wall Abutment — flashing that shields the area where roof edges meet walls

Why is Flashing So Important?

Flashing — regardless of the material or type — is crucial in the water resistance of your commercial roof. Low-slope roofs often do not shed water as fast as steep-slope or residential roofs, so the longer water remains stagnant, the longer it has to find weak spots in your roof. Along with caulking and sealing, applying roof flashing helps prevent roof leaks and keeps your property sturdy and safe for everyone going in and out of your building.

Looking for a trusted contractor for your commercial roof installation? Give International Construction Services, Inc. a call today! You can reach us at (803) 699-5106. You can also fill out our contact form to get a FREE consultation.